Metal Cutting Inserts

References for some of the inserts I have come across so far. Will be adding more as I find uses for them.

1604 Inserts

Inserts for Cutting Aluminum, Carbide Uncoated: https://amzn.to/4cfGU2F

Inserts for Cutting Steel: https://amzn.to/41VDXkf

Inserts for Cutting Stainless Steel: https://amzn.to/42nKu6u

Inserts To Test: https://amzn.to/41VELFN

Dimensions Specs and Speeds: https://www.shop-apt.co.uk/carbide-inserts-for-milling-uni-tip/apkt-1604-pdr-um25-carbide-milling-inserts-pvd-coated-for-steel-stainless.html

APKT1003 Inserts

Carbide Inserts PVD for Steel and Stainless Steel: https://amzn.to/41TCjj8

Carbide Insert with PVD for Steel and Stainless Steel: https://amzn.to/4l8UzfT

Dimensions Specs and Speeds: https://www.shop-apt.co.uk/carbide-inserts-for-milling-uni-tip/apkt-1003-pdr-um30-carbide-inserts-for-milling-pvd-coated-for-stainless.html

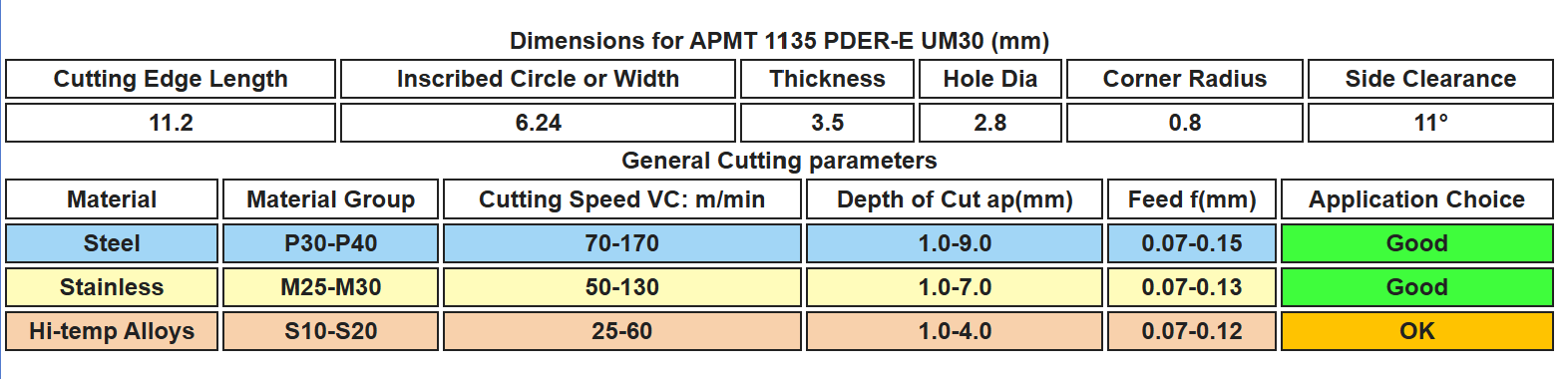

1135 Inserts

Steel Cutting Inserts: https://amzn.to/3FS2MFj

Aluminum Cutting Inserts: https://amzn.to/42uJE8U

Stainless Cutting Insert: https://amzn.to/4jbvgIZ

Carbide Inserts for Steel and Cast Iron: https://amzn.to/4hVJrQH

PVD Coated for Steel: https://amzn.to/4lg9YLp

Dimensions Specs and Speeds: https://www.shop-apt.co.uk/carbide-inserts-for-milling-uni-tip/apmt-1135-pder-e-um30-carbide-inserts-for-milling-pvd-coated-for-stainless.html

Basic Bits Overview

Video 2: https://www.youtube.com/watch?v=6PnAZlMlT3k

Summary for choosing the best bit. Chose the largest diameter and shortest cutting length you can do for the job. The harder the material the more flutes your cutter you should have. Wood & Plastics 1-2 flute, Aluminum = 2-3 flute. 4 flute = aluminum or Steel. Cemented Carbide for Steel & Aluminum since it is hard and rigid and holds edge. HHS (Hight speed steel) Cheaper, Good for wood and plastic, Used to be used for Aluminum but Carbide is more common now. Use insertable face mill or end mill when possible. Insertable endmills are excellent for roughing. HSS is primarily just used for manual mills, and small CNC mills. Large CNC almost exclusively uses carbide and it is often used for manual and small CNC as well.

https://www.youtube.com/watch?v=p08xIYxZBLo

End mill coatings aren’t necessary for aluminum and can be a problem if they have Al in them, ZRN will work well for Aluminum. Never cut aluminum dry. Always use coolant. Best option is either 2 or 3 flute. 2 flute is better for ramping and plunging. 3 flute is better for finishing. Angle of the flute around 40 degrees is excellent for overall. 60 degree flute angle is great for finishing.

Note: We attempt to find the best balance between quality and price. However, many of these parts are made in China and the quality may vary over time. Please check your parts before the return window ends.

Additional Bit Analysis

Aluminum Cutting Mill Bits

Video 1: Discusses number of flutes for best work. https://www.youtube.com/watch?v=pHZHplzMf6o

Summary: 1 flute good for soft materials like aluminum. 2 flute is good for rough work, plunges and evacuates the chips. 3 flute good general tool for both rough and finishing with chip evacuation. 5 flute is good for finishing.

Video 2: https://www.youtube.com/watch?v=6PnAZlMlT3k

Summary for choosing the best bit. Chose the largest diameter and shortest cutting length you can do for the job. The harder the material the more flutes your cutter you should have. Wood & Plastics 1-2 flute, Aluminum = 2-3 flute. 4 flute = aluminum or Steel. Cemented Carbide for Steel & Aluminum since it is hard and rigid and holds edge. HHS (Hight speed steel) Cheaper, Good for wood and plastic, Used to be used for Aluminum but Carbide is more common now. Use insertable face mill or end mill when possible. Insertable endmills are excellent for roughing. HSS is primarily just used for manual mills, and small CNC mills. Large CNC almost exclusively uses carbide and it is often used for manual and small CNC as well.

https://www.youtube.com/watch?v=p08xIYxZBLo

End mill coatings aren’t necessary for aluminum and can be a problem if they have Al in them, ZRN will work well for Aluminum. Never cut aluminum dry. Always use coolant. Best option is either 2 or 3 flute. 2 flute is better for ramping and plunging. 3 flute is better for finishing. Angle of the flute around 40 degrees is excellent for overall. 60 degree flute angle is great for finishing.

TiAlN Coated Cobalt https://amzn.to/41OwAtB

Note 1: We attempt to find the best balance between quality and price. However, many of these parts are made in China and the quality may vary over time. Please check your parts before the return window ends.

Note 2: When you click links to various merchants on this site and make a purchase, this can result in this site earning a commission.